S7-300 CPU

Description

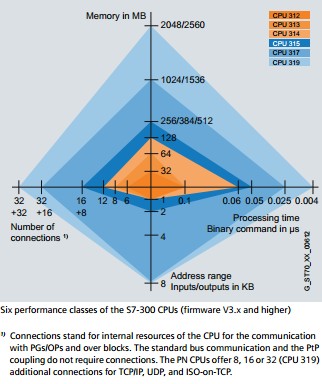

Six performance classes of the S7-300 CPUs

A graded CPU range with a wide performance range is available for configuring the controller.

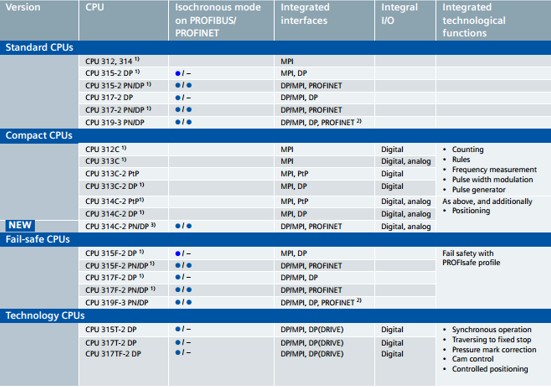

The product range comprises 7 standard CPUs,

7 compact CPUs, 5 fail-safe CPUs and 3 technology CPUs.

The CPUs are available from a width of only 40 mm

SIMATIC S7-300 is within Totally Integrated Automation the most sold Controller.

Range of application

• In the first instance SIMATIC S7-300 is used for innovative system solutions in manufacturing technology, especially for automobile industry, mechanical engineering in general and especially for special machine building and serial production of machines (OEM), at plastics processing, packaging industry, food and beverage industry and process engineering

• As an all-purpose automation system is S7-300 the ideal solution for applications, which need a flexible concept for central as well as local configuration

• For applications, which require a especial robustness because of surrounding conditions, we have the SIPLUS extreme devices Particularly in the finishing technique the S7-300 is used in the following industries:

• Automobile industry

• General mechanical engineering

• Building of special machines

• Series mechanical engineering, OEM

• Plastics processing

• Packaging industry

• Food and Beverage industry

• Process engineering

• Fast counting/fairs with direct access on the hardware counters

• Simply positioning with direct control the MICROMASTER frequency static frequency changers

• PID-Regulation with integrated functional module

Benefits

• Thanks to their high processing speed, the CPUs enable short machine cycle times.

• The S7-300's range of CPUs provides the right solution for every application, and customers only pay for the performance actually required for a specific task

• The S7-300 can be set up in a modular configuration without the need for slot rules for I/O modules

• There is a wide range of modules available both for the centralized and the distributed configuration with ET 200M.

• Integral PROFINET interfaces enable simple networking of the controllers, and simple data exchange with the operations management level

• The narrow module width results in a compact controller design or a small control cabinet.

• The ability to integrate powerful CPUs with Industrial Ethernet/PROFINET interface, integrated technological functions, or fail-safe designs make additional investments unnecessary.

Design and function

Tabel CPU Innovations

Design

The S7-300 enables space-saving and modular configurations. In addition to the modules, only a DIN rail is required for hooking in the modules and screwing them into place.

This results in a rugged and EMC-compatible design.

The build-as-you-go backplane bus can be expanded by simply plugging in additional modules and bus connectors. The varied range of the S7-300 can also be used for centra lexpansions or the construction of distributed structures with ET 200M; thereby producing very cost-effective spare parts handling.

Expansion options

If the automation task requires more than 8 modules, the central controller (CC) of the S7-300 can be expanded using expansion units (EUs) Up to 32 modules can be used in the centralrack and up to 8 per expansion unit. Interface modules(IMs) handle communication between the individual racksautonomously. In the case of plants covering wide areas, CCs/EUs can also be installed at greater distances from eachother (up to 10 m).

In a single-tiered configuration, this results in a maximumconfiguration of 256 I/O, and in multi-tiered configurations upto 1024 I/O. In distributed configurations with PROFIBUS DP,65536 I/O connections are possible (up to 125 stations, suchas ET 200M via IM 153). The slots are freely addressable, thatis, there are no slot rules.

The extensive range of S7-300 modules is also used in distributedautomation solutions.

The ET 200M I/O system that hasthe same construction as the S7-300 can be connected via Interface modules not only to PROFIBUS but also to PROFINET.

To the top of the page

Technical data

CPU Range

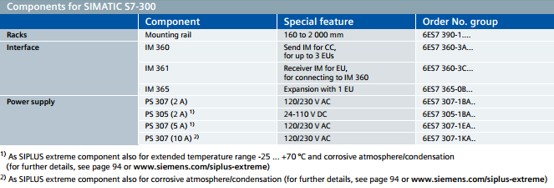

Components for SIMATIC S7-300

Edit Content

Edit Content.gif)

.gif)

.gif)